Choosing the Right Electric Motor Enclosure

Are you making sure to choose the best motor for your application and environment to replace your failed motor? While matching the frame size, horsepower, RPM, and voltage is the easy part, it may not always be the best choice to simply replace your motor with one that matches the same enclosure as before.

It’s crucial to consider what enclosure is most suitable for the environment in which the motor will be installed. You don’t want to continue with the same mistake that was made when the original motor was selected. Often, equipment OEMs select a motor based on cost rather than what’s best for the motor’s longevity of service.

While selecting the motor enclosure, do check what type of cooling is required by the motor and what temperature and environment is required for its operation.

Open Drip Proof (ODP) motorsare the least expensive of all the motors and therefore it is the generally preference of equipment OEMs. These motors work well indoors in an environment free of airborne contaminants.

ODP motors allow for the free flow of cooling air. The open design of these motors allows anything in the surrounding environment to be pulled through the motor by the internal cooling fans. The fans not only pull dust and dirt through the motor but also any humidity in the motor’s surrounding area.

The combination of moisture, dust, and dirt adheres to the windings, blocking cooling vents within the stator laminations and causing the motor to operate at temperatures that exceed the insulation limits, shortening the motor’s life.

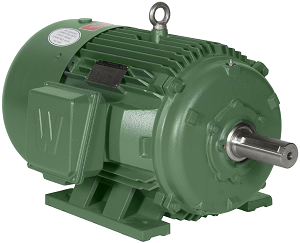

Totally Enclosed Fan Cooled (TEFC) motors, although slightly more expensive than ODP motors, are usually cheaper in terms of total cost of ownership. This type of motor is designed for applications where contaminants are factors, such as paper mills, chemical plants, and motors used outdoors.

TEFC motors provide exterior cooling, where a fan and fan cover direct air across the outside of the motor and over the cooling fins. A periodic visual inspection of the motor should be performed to ensure that there is no buildup of contaminants on the skin of the motor, which would cause it to operate at a temperature higher than its design. With proper maintenance, TEFC motors will far exceed the life of an ODP motor.

Although the two enclosures described above are the most common, there are several others that can be used for specific environments and applications. The most important thing to remember is that you have options when replacing a motor. Contact a qualified company that has the expertise to assist you in selecting the best option for your needs.